Operating procedure for tetrahydrothiophene filling

Filling operation procedures

1、Confirm the site safety conditions, tetrahydrothiophene tank acceptance conditions.

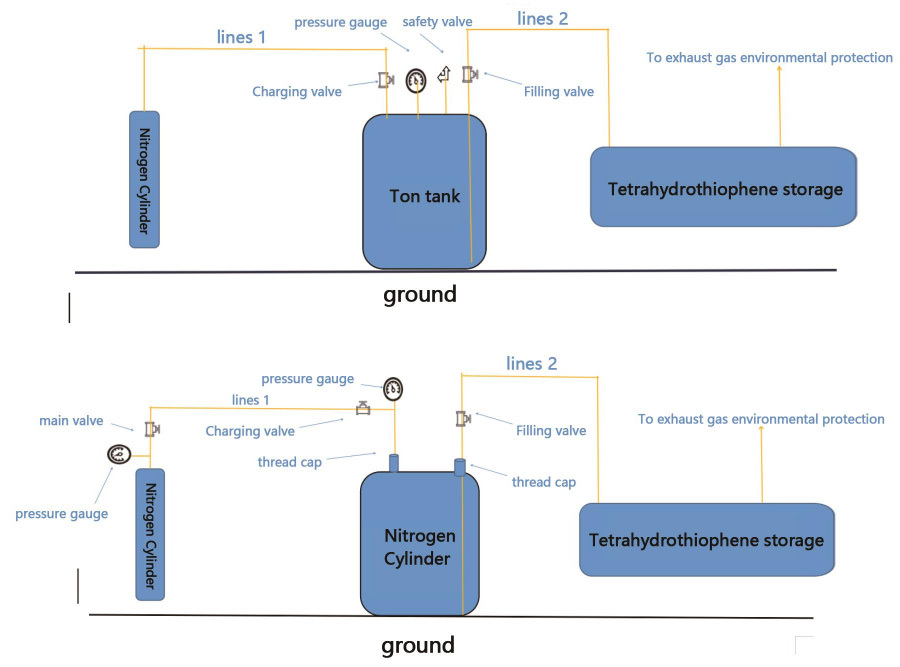

2、Nitrogen gas bottle nitrogen is used to blow nitrogen to lines 1and 2 in the schematic diagram.

3、Install pipeline 1 and pipeline 2 with thread cover / ton tank to ensure no air leakage.

4、Close the filing valve, slightly open the filling valve, and focus on the nitrogen bottleZ pressure gauge pressure filling to0.03Mpa-0.04Mpa(or 30-40 Kpa).

5、When the pressure is reached, close the filling valve and slowly open the filling valve.

6、Close the filling valve with the pressure below 0.01 Mpa (10 Kpa) and recharge the pressure valve. Repeat the operation in turn until the filling is complete.

7,When the filling level is low, the filling pressure is 0.02-0.03Mpa, and the frequency of filing is increased

8、Close the filling valve and filling valve. After removing the pipeline, seal the pipeline interface with a plug

matters need attention

1、Fireworks and the use of mobile phones are strictly prohibited for on-site operation.

2、During the filling process of the packaging bucket, pay close attention to the shape change of the packaging bucket. f2there is deformation, immediately stop the pressure filling, close the flling valve, and slightly open the filing valve to relievethe pressure.

3、When the liquid level is low in the late filing stage, the filling pressure should be strictly controlled for not exceeding 0.063Mpa to prevent the serial pressure to the tetrahydrothiophene storage tank.

4、The filling interval is at least 10 seconds to ensure that the pressure in the packaging bucket is stable.

5、The filling personnel must hold the R1 pressure vessel operation certificate.

6、Strictly implement the filling pressure without filling, filling pressure without filling pressure.

Fill diagram of packing bucket / :